Product

INSPECTIFAI means both Quality and Efficiency

Committed to achieving greater drug and patient safety for pharmaceutical companies, our customers no longer have to choose between product quality and efficiency. With InspectifAI, we succeed both and create yearly savings in the millions.

Our Benefits

Minimize requalification efforts

Achieve higher machine throughput

Speed up recipe optimizations

Minimize recipe landscape

Shorten time-2-inspection for new products

Positive impact on sustainability

The Problem we tackle

Pharmaceutical manufacturing is subject to strict regulatory requirements. This includes a 100% quality control of each pharmaceutical product once filled. Automatic Visual Inspection (AVI) is already common practice in the industry, being more precise and faster than traditional manual quality control. Yet, even with AVI, high False Reject Rates occur frequently. The result? Extensive secondary inspection and high costs.

INSPECTIFAI EMBRAICE

Our AI software solution condenses the knowledge and experience of inspection specialists and makes it accessible to Automated Visual Inspection. Improving the decision-making on product quality, our AI models reduce False Rejects and thus reinspection efforts to a minimum.

Book a demo

Edge Excellence

We empower even older vision systems and AVI’s to use and leverage the advantages of AI. Besides computational power, additional features enable real-time image acquisition during commercial production for further performance optimizations.

Software Excellence

AI empowers the visual inspection process, significantly reducing manual efforts and time-consuming tasks. This enables faster and more accurate defect detection, minimizes requalification efforts, and assures higher machine throughput. With AI as your ally, streamline workflows, expedite production, and maximize operational efficiency!

AI Excellence

We ensure to train the right AI model and train the AI model right. Mastering a portfolio of AI models, we ensure to make the right decision for your individual vision problem.

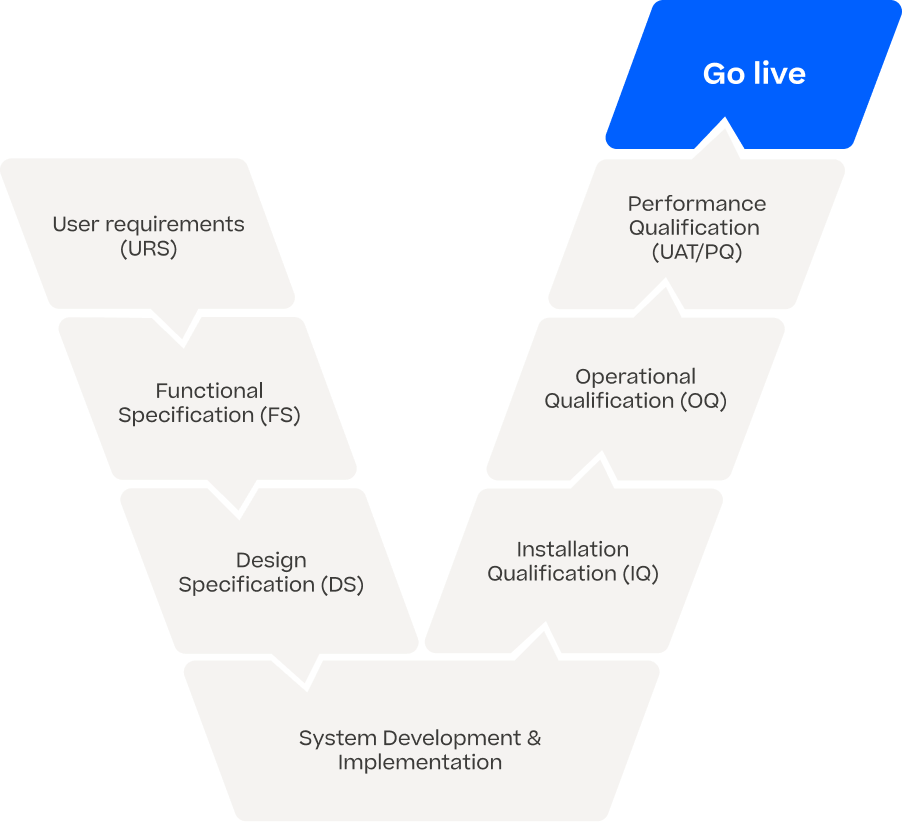

Compliance Excellence

We ensure GxP compliance with our internal processes, our product development, as well as our solution implementation on your site including the qualification processes supported by our documentation.

Regulatory Compliance

With our end-to-end solution, we ensure regulatory-compliant AI on a wide variety of vision applications and Automated Visual Inspection systems without any significant changes or requalification efforts on your machine. We work GxP compliant in developing state-of-the-art software and bringing INSPECTIFAI EMBRAICE onto your vision system. Our documentation and validation package is part of our delivery and makes AI applicable in the regulated industry.